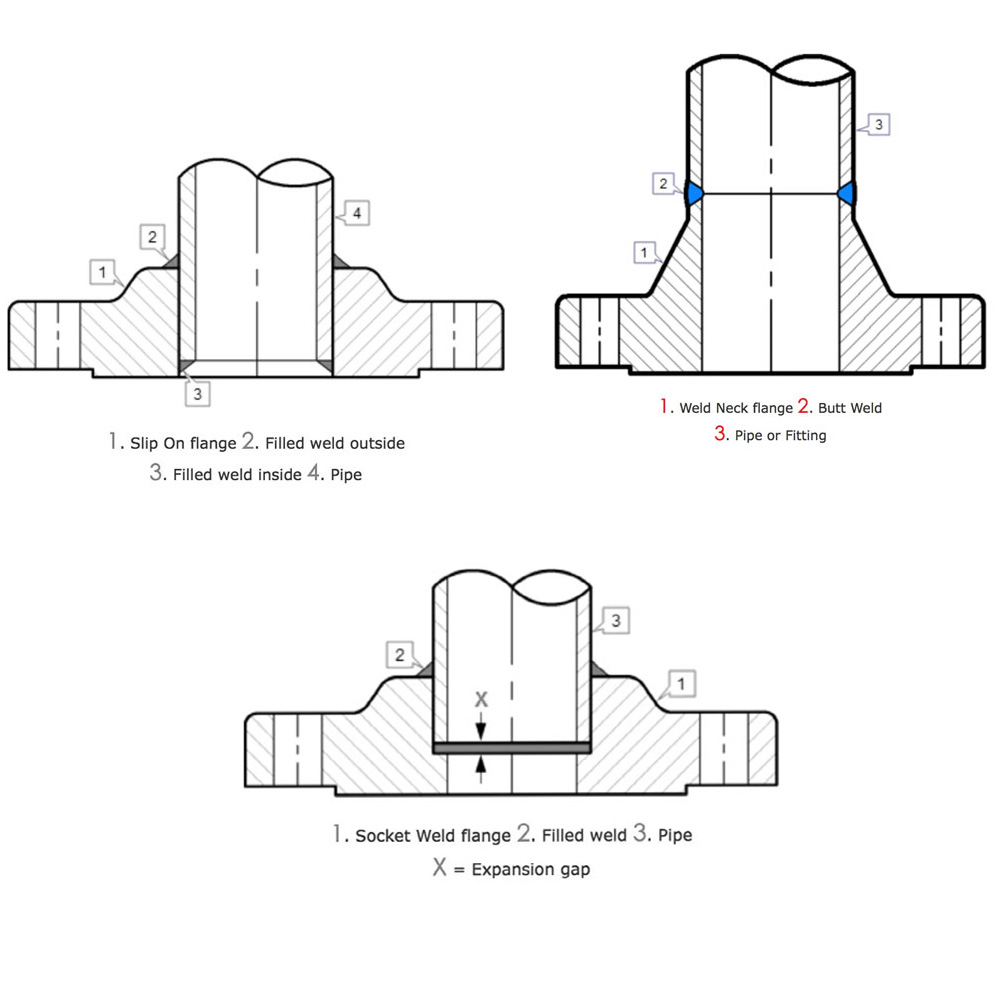

1.Flat kuwotcherera, matako kuwotcherera ndi socket kuwotcherera flange

Kuwotcherera kwa chitoliro kumakhala ngati kuwotcherera kwa lathyathyathya, kuwotcherera kwa matako ndi zitsulo zowotcherera flange

Socket welding nthawi zambiri imalowetsa chitoliro muflangeza kuwotcherera.Kuwotcherera matako ndikuwotcherera chitoliro ndi matako pamwamba pakematako kuwotcherera flange, Kuzindikira kwa ray sikungathe kuchitidwa pazitsulo zowotcherera, koma kuwotcherera kwa matako kungatheke.

2. Zosiyanasiyana ndi ntchito

Nthawi zambiri, zofunika kuwotcherera matako ndi apamwamba kuposa kuwotcherera zitsulo, ndipo khalidwe pambuyo kuwotcherera ndi zabwino, koma njira kuzindikira ndi okhwima.Kuwotcherera kuti muzindikire zolakwika za ray, kuwotcherera kwa socket kuchita maginito ufa kapena kuyesa kolowera kumatha kukhala (monga chitsulo cha kaboni chimapanga maginito ufa, chitsulo chosapanga dzimbiri chimalowa).Ngati madzimadzi mu payipi safuna kuwotcherera mkulu, tikulimbikitsidwa kugwiritsa ntchito kuwotcherera socket kuti azindikire mosavuta.

Ambiri mwa kugwirizana mitundu kuwotcherera zitsulo ntchito yaing'ono mavavu awiri ndi mapaipi, zovekera chitoliro ndi kuwotcherera mapaipi.Mapaipi aang'ono ang'onoang'ono nthawi zambiri amakhala opyapyala mu makulidwe a khoma, osavuta kusanja molakwika ndi kuchotsedwa, komanso ovuta kuwotcherera, motero amakhala oyenera kuwotcherera socket.Kuonjezera apo, zitsulo zazitsulo zowotcherera zimakhala ndi mphamvu zowonjezera, choncho zimagwiritsidwanso ntchito pansi pa zovuta kwambiri.Komabe, kuwotcherera socket kulinso ndi zovuta zake.Chimodzi ndi chakuti vuto la kupsinjika pambuyo pa kuwotcherera silili bwino, ndipo n'zosavuta kuyambitsa kulowa kosakwanira kwa kuwotcherera.Pali mipata mu dongosolo la chitoliro.Choncho, kuwotcherera zitsulo si oyenera dongosolo chitoliro ntchito mpata dzimbiri tcheru sing'anga ndi chitoliro ndi zofunika ukhondo mkulu.Kuphatikiza apo, mapaipi opitilira muyeso, ngakhale makulidwe a khoma la mapaipi ang'onoang'ono ang'onoang'ono alinso akulu, amatha kulumikizana ndi matako momwe angathere kuti apewe kuwotcherera kwa socket.

Mwachidule, kuwotcherera zitsulo kumapanga fillet weld, pomwe kuwotcherera matako kumapanga butt weld.Kuchokera pakuwunika mphamvu ndi kupsinjika kwa weld, cholumikizira chathako ndichabwino kuposa cholumikizira cha socket, kotero cholumikizira chathako chiyenera kugwiritsidwa ntchito ngati pali kupanikizika kwakukulu komanso kusagwira bwino ntchito.

3. Kusankhidwa kwa flange

1. Malinga ndi zinthu za payipi kusankha zinthu zenizeni zoyenera za flange, monga payipi yachitsulo chosapanga dzimbiri sikuloledwa kusankha.carbon steel flange ;

2. Malinga ndi m'mimba mwake (DN) wa payipi ndi kuthamanga kwadzina (PN) kwa dongosolo lonse la mapaipi, kumanjaflangeamasankhidwa.Pakali pano, mayikopayipi flangemakamaka utenga American muyezo dongosolo ndi European muyezo dongosolo;

3. Malingana ndi zochitika zenizeni zogwirira ntchito, mawonekedwe a flange ndi mawonekedwe amasankhidwa: monga kuwotcherera lathyathyathya ndi khosi, loop flange, etc., ndi kusindikiza pamwamba kumakhala ndi pamwamba, ndege yonse, concave ndi convex pamwamba, etc. .

Kwa magawo omwe siawongoleredwa, ndikofunikira kupanga ndi kupanga molingana ndi momwe flange imapangidwira.

Nthawi yotumiza: Feb-20-2023